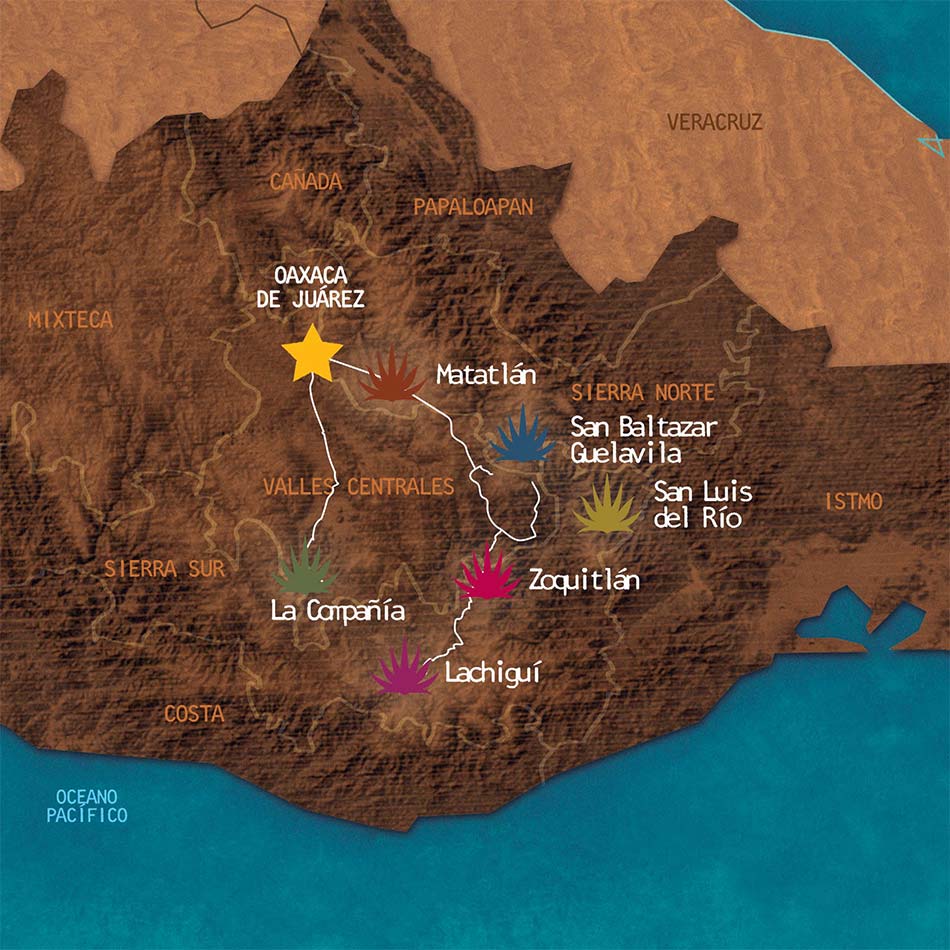

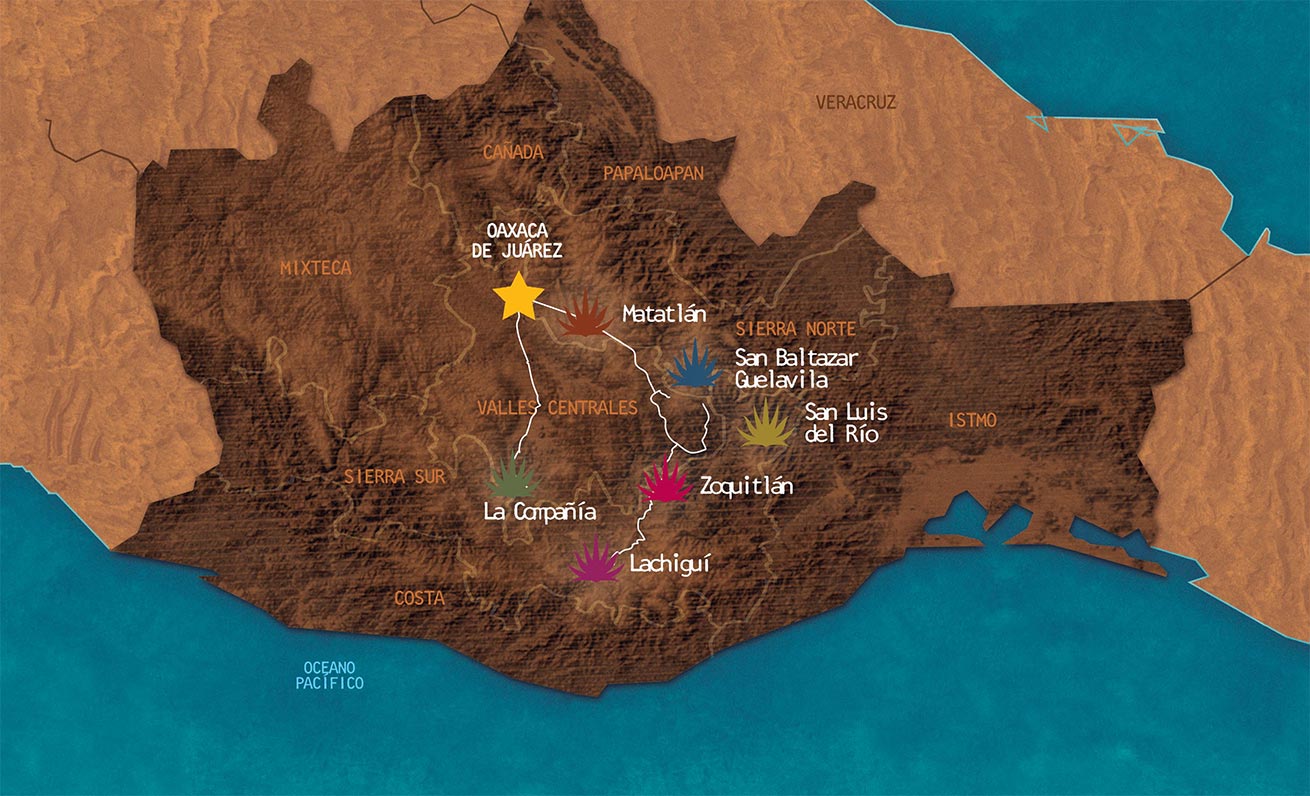

The rural town of Santiago Matatlán, just to the east of Oaxaca City in the Valles Centrales region, is widely known as the epicenter for traditional mezcal production. Many small villages in Oaxaca are known for an art, craft, or trade that artisans in the village specialize in. In Santiago Matatlán, it is mezcal they are known and celebrated for, and have been for generations. The Espadín agave harvested by the Cortés family to produce this expression of Nuestra Soledad grows at an elevation of 5,500-5,900 feet in a mountain canyon rich with agave diversity. Amongst stunning vistas, the Espadín agaves for this mezcal are sustainably cultivated alongside wild outcrops of Tepeztate, Tobalá and Coyote agaves. Mezcalero Gregorio Martinez Jarquín has been working in Santiago Matatlán since he was a teenager and is widely respected in the mezcalero community.

| Type | Mezcal |

|---|---|

| Variety | Espadín |

| Volume | 750 mL |

| ABV | 48% |

| Country of Origin | Mexico |

| Region/CRU | Santiago Matatlán, Tlacolula |

| Flavor | Roasted plantain and savory smoked meats, toasted cacao nibs. |

|---|---|

| Finish | Robust, but balanced wood-smoke finish. |

San Luis del Rio is a small village in the district of Tlacolula, nestled into the steep hillside along a deep river valley in the mountains to the east of the Valles Centrales region of Oaxaca. Intense heat in the region results in early-ripening agave with densely concentrated sugars leading to the bold, fruity, complex profile of this mezcal. San Luis del Rio is one of the epicenters of mezcal production and almost exclusively produces Espadín. The tiny distilleries that are spread out along the river benefit from the shade from tropical fruit-bearing trees and nearby water source. Above the tree line at higher elevation, conditions are rugged and ideal for the cultivation of Espadín, with parcels of agaves plantations dotting the mountainside as far as the eye can see. It is here that Ivan and Paco Méndez uphold the legacy of their late father, Don Rafael Méndez Cruz, whose contribution to his community was immense, not only as a family man and mezcalero, but as a proponent of cultural preservation in San Luis del Rio.

| Type | Mezcal |

|---|---|

| Variety | Espadín |

| Volume | 750 mL |

| ABV | 48% |

| Country of Origin | Mexico |

| Region/CRU | San Luis del Rio, Tlacolula |

| Aroma | Sparkling grapefruit and citrus aromatics with wet stone. The palate has a rich and creamy mouth-feel, savory butterscotch and herbs with a long and complex finish. |

|---|

Nestled into the side of a steep ravine, hours from civilization, the ranch settlement of Lachiguí is home to the Vasquez family of mezcaleros. The ranch itself is a tiny complex of humble structures that house members of extended family with the nearby small village of El Palmar some 30 minutes drive along precipitous, mountainside dirt roads. At 7,414 feet elevation, Lachiguí is the highest elevation palenque of those producing mezcal for the Nuestra Soledad brand, by over 1,500 feet. Tio Pedro’s agave fields are a 500 foot elevation climb up the mountain from the palenque, home to a treasury of various agave varieties planted in rocky soil laden with limestone. The extreme growing conditions produce some of the most complex mezcals with elegance and nuance that complements their massive strength. Pedro Vasquez is a master of his craft and produces many of the most prized expressions of the El Jolgorio mezcals including Arroqueño, Tobalá, and Tepeztate.

| Type | Mezcal |

|---|---|

| Variety | Espadín |

| Volume | 750 mL |

| ABV | 48% |

| Country of Origin | Mexico |

| Region/CRU | El Palmar, Miahuatlán |

| Aroma | Richly aromatic with notes of wet earth, fresh cherries, cedar wood and cigar box, peppery and green on the palate with bright, citrusy acidity and a long, dry earthy/woody finish |

|---|

San Baltazar Guelavila is a small town on the eastern side of the Valles Centrales region of Oaxaca, Mexico in the district of Tlacolula. It is in these valley highlands, because of their fertile, limestone soils, that espadín has been cultivated for over 100 years alongside other sustaining crops. Don Gregorio Martinez grows his espadín at an elevation of 5,500 feet surrounded by diverse agriculture such as tropical fruits and citrus. The proliferation of fruits and vegetables being grown in the area lend their naturally occurring yeasts to the wild fermentation process and give this mezcal it’s distinctive sparkling aromatics and rich flavor.

| Type | Mezcal |

|---|---|

| Variety | Espadín |

| Volume | 750 mL |

| ABV | 48% |

| Country of Origin | Mexico |

| Region/CRU | San Baltazar Guelavila, Tlacolula |

| Flavor | Sweet, ripe, tropical fruit, caramelized agave, Chinese five spice and wet stone on the nose. |

|---|---|

| Finish | Mineral-rich, and round mouth-feel with an exceptionally long and complex wood-smoke and finish |

La Compañía is a small village in the district of Ejutla, southwest of Oaxaca City in the Valles Centrales Region. The La Soledad distillery is owned and operated by Gregorio Hernandez, along with his sons Valentín and Joel, and is situated on a hilly plateau at an elevation of 5,000 feet above sea level. The steep slopes favor hardy agaves and the struggle to survive in this harsh growing environment comes through in the complexity of their mezcal. Don Gregorio employs a method of distillation that is common in the region of Ejutla, using a single, extended distillation in a modified pot still with a cooling chamber called a refrescador, which contributes to the unique, bold flavor profile.

| Type | Mezcal |

|---|---|

| Variety | Espadín |

| Volume | 750 mL |

| ABV | 48% |

| Country of Origin | Mexico |

| Region/CRU | Agua del Espino, La Compañia, Ejutla |

| Aroma | Bright and aromatically complex with white flowers, cilantro, and mint on the nose. |

|---|---|

| Flavor | Rich, savory, and viscous on the palate with roasted chiles and minerality. |

| Finish | The finish is long with a delicate kiss of wood smoke. |

Santa María Zoquitlán is a village of roughly 1,600 people, set within a wondrous territory of rugged ridgelines and sweeping river basins, southeast of Santiago Matatlán. This small town is cradled by two converging river valleys and flanked with steep hillsides studded with rare agaves In the dry season, the rugged, brown vegetation blends into the rocky cliffs behind. After the rains, the region takes on a verdant hue, thanks to the rising, jade-green Zoquitlán River that winds through the valley floor, making the area rich for cultivating a wide variety of sustaining crops. Ignacio Parada, known as Don Chucho, along with his son José Parada Valera, harvest wild and semi-cultivated agaves from the rich, multi-colored mountain soils directly behind their palenque. Don ChuCho was the first mezcalero to join the Casa Cortés collective of producers in 2007. Today, he is proud to be passing along his craft to the next generation as he works side-by-side with his son to produce mezcals for Nuestra Soledad and El Jolgorio.

| Type | Mezcal |

|---|---|

| Variety | Espadín |

| Volume | 750 mL |

| ABV | 48% |

| Country of Origin | Mexico |

| Region/CRU | Santa María Zoquitlán, Tlacolula |

| Aroma | Lemon zest, red pepper, tropical fruit and smoked game greet the nose. |

|---|---|

| Flavor | Big, creamy, mouthfeel, with complex palate featuring honeysuckle and sandalwood. |

| Finish | Exotic finish is long and nuanced with lychee, stone fruit, and savory herbs. |

Rolando Cortés, son of Don José Cortés, is a 5th generation member of the Cortés family and serves as CEO of the Casa Cortés company. After growing up in his family's palenque in Santiago Matatlán, Rolando's mezcal journey eventually took him to San Francisco for a period in his twenties, where he gained exposure to the spirits market in the United States. In the early 2000's, Rolando led his family's efforts at breaking into a small, but growing market with the Agave de Cortés brand. In 2010, with the mezcal category still in a nascent stage, Rolando's vision led his family to begin bottling their mezcal for international distribution under the El Jolgorio and Nuestra Soledad brands followed by the re-introduction of the Agave de Cortés brand. Rolando's goal in all of his work was to honor his family's Zapotec heritage and preserve the deep cultural ties that his family has to mezcal.

Once the agaves are harvested, they are taken back to the palenque (pr. pah-lane-kay) or distillery. Most traditional palenques consist of generally the same elements:

After many years of uninterrupted growth in the field, the wild agave plant reaches maturation. At this stage, the agave is preparing to flower and begins to condense sugars and nutrients in its center, making it ripe for harvest. After observing and nurturing the agave for many years (up to 25 years in the case of the wild agave Tepeztate), palenqueros select only the best wild agave. With a machete or ax, the long, stiff leaves are sheared, leaving a piña, or the heart of the agave, which gets its name from its resemblance to a pineapple.

The mezcalero depends on the land for his livelihood, and routinely talks to the land, thankful for its provisions.

Roasting agaves in preparation for crushing takes many years of expertise to master. Every Master Distiller has his own methods and techniques, making every Nuestra Soledad mezcal unique. During the roast, the heat breaks down the complex sugars in the agave into simple sugars, making them suitable for fermentation.

First, a hot fire is built in an earthen pit-oven, fueled by oak and eucalyptus, and often lined with volcanic or river rocks to absorb and maintain the heat. When the pit is hot enough, the piñas are stacked in the pit over the fire and hot rocks, then covered with any of a variety of materials, including a thick layer of dirt, fibrous agave leaves, and soaked burlap, creating an underground oven. Roasting agave imparts the smokiness typically associated with Mezcal.

Once roasted, the soft, brown agaves are chopped into smaller pieces and placed in a small, round pit to be ground into fibrous candy-like strands, releasing the caramelized sugars and juices that were condensed during the roast.

Traditionally, the palenque employs a mule or horse pulling a round tahona stone to speed the process.

Nuestra Soledad's Master Distillers each use traditional methods passed down from father to son over many generations. Thus, traditional mezcal is made the exact same way it was centuries ago.

After roasting and grinding, the mashed agave is placed into large wooden tanks, and local-source water is added. Upon mingling with open air and wild yeast, the fermentation process begins, often lasting from 6 - 10 days. The fermenting mash is called mosto.

The fermented agave mash is distilled twice in copper stills, set atop a wood-oven. As the spirit evaporates and rises in the still, it is trapped and run through a serpentine pipe submerged in cold water, causing the spirit vapors to condense into liquid form.

After the first distillation, the spirit is approximately 37% abv, and increases to approximately 52-55% upon the second distillation.

Using centuries old methods, and many years of experience, the mezcalero is able to determine the proof of the second distillation simply by blowing through a bamboo-like tube into a cup of mezcal to create bubbles. The larger the bubbles, the higher the proof.

| Ingredients | |

|---|---|

| 1.5 oz. | Lustau Oloroso |

| .75 oz. | Giffard Banane du Bresil |

| 1 Barspoon | St. Elizabeth's Allspice dram |

| 1 Barspoon | Nuestra Soledad Ejutla |

| 2 Dashes | Bitterman's Tiki Bitters |

| Method |

|---|

| Stir all ingredients with ice and pour into chilled Nick & Nora. |

| Express lemon peel over cocktail. |

| Discard lemon peel. |

| Garnish |

|---|

| Lemon Twist |

| Equipment |

|---|

| Nick & Nora Glassware |

| Ingredients | |

|---|---|

| 2.0 oz. | Angelisco Reposado |

| 0.5 oz. | Nuestra Soledad San Luis del Rio |

| 0.25 oz. | Agave Syrup |

| 2 dashes | Angostura Bitters |

| Method |

|---|

| Combine ingredients in a rocks glass with ice and stir. |

| Top up with ice. |

| Garnish with large orange peel. |

| Garnish |

|---|

| Large orange peel |